Medium Voltage Cable

With a comprehensive range of Medium Voltage cables, our MV testing laboratory, and experts to provide technical and regulatory advice, Eland Cables is an MV specialist.

There's huge variations in construction, standards and the materials used - specifying the correct MV cable for a project is a matter of balancing the performance requirements, installation demands, and environmental challenges, and then ensuring cable, industry, and regulatory compliance. With the International Electrotechnical Commission (IEC) defining Medium Voltage cables as having a voltage rating of above 1kV up to 100kV that's a broad voltage range to consider. It's more common to think as we do in terms of 3.3kV to 69kV, before it becomes high voltage. We can support cable specifications in all voltages.

Medium Voltage Cable Standards & References:

These are the standards and references most commonly used - with technical datasheets for the cables also provided below.

| MV Cable Standard |

MV Standard Description |

|---|---|

| IEC 60502-2 | Cables with extruded insulation with voltage rating between 6kV and 30kV |

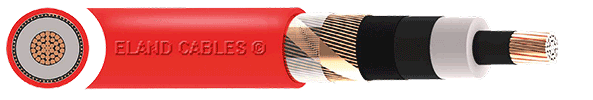

| Single core Copper (N) or Aluminium (NA) XLPE/LSZH cables in accordance with IEC60502-2 with optional single or dual waterblocking. Available as 3-core variants under references N2XSEH / NA2XSEH. | |

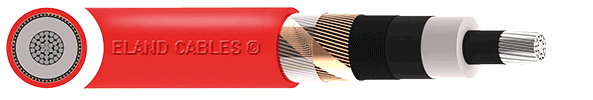

| Single core Copper (N) or Aluminium (NA) XLPE/MDPE cables in accordance with IEC60502-2 with optional single or dual waterblocking. Available as 3-core variants under references N2XSE2Y / NA2XSE2Y. | |

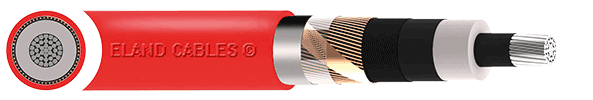

| Single core Copper (N) or Aluminium (NA) XLPE/PVC cables in accordance with IEC60502-2. Available as 3-core variants under references N2XSEY. | |

| BS6622 | Armoured cable with PVC outer sheathing and voltage rating from 3.3/6kV to 19/33kV - AWA single core, SWA multicore. |

| BS7835 | Armoured cable with LSZH outer sheathing and voltage rating from 3.3/6kV to 19/33kV - AWA single core, SWA multicore. |

| BS7870-4.10 | Single core cables for distribution utilities with extruded insulation up to and including 11kV and 33kV |

| HD620 | Cables with extruded insulation and voltage ratings 3.6/6 (7.2)kV to 20.8/36 (42)kV (often seen in conjunction with IEC60502-2) |

| DIN VDE 0276 Part 620 | Distribution cables of nominal voltages 3.6kV to 20.8/36kV |

Whilst the German nomenclature for IEC60502-2 cables (eg: N2XSH) is widely used, there are other naming conventions also in use - Portuguese Medium Voltage cables include references LXHIOE and XHIOAV. Our team can support specification against all references, regardless of geography.

Medium Voltage Cable Datasheets - Selecting the right MV Cable for your project

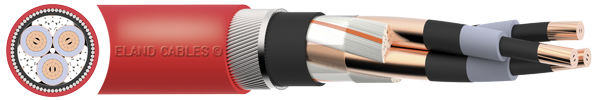

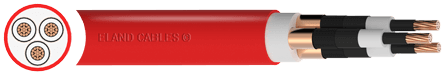

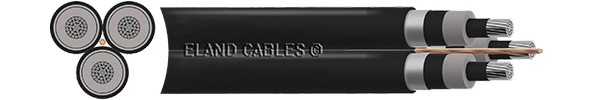

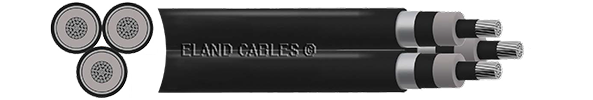

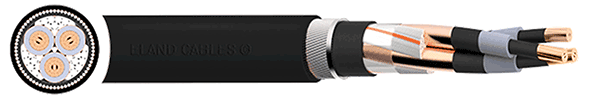

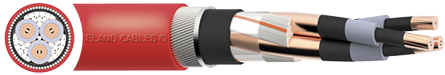

There are many options for construction, standards, and the materials used. The format can be single core, three core, or single core triplex. The details below and the technical datasheets provided as PDF downloads are the most commonly specified but variations can be supported.

All MV Cable datasheets will provide guidance on application, construction & materials, relevant standards, cable sizes, and electrical characteristics. In the event that further information is required to support specification, or the parameters required do not match any of the listed cable PDF datasheets, please speak to a member of the team who will be able to assist you.

Medium Voltage Cable Construction:

Construction will influenced by the installation environment but it will include the following:

| MV Cable Layer | MV Cable Materials |

|---|---|

| Conductor | Copper or Aluminium - Class 1 solid, Class 2 stranded (circular, circular compacted, sectorial). Some flexible MV cables for dynamic equipment also available. |

| Optional: Conductor Waterblocking | Swellable powders or swellable yarns in stranded interstices |

| Conductor Screen | Semi-Conductive Layer |

| Insulation | XLPE (Cross-linked Polyethylene) or EPR (Ethylene Propylene Rubber) |

| Insulation Screen | Semi-Conductive Layer |

| Optional: Waterblocking - Longitudinal | Swellable powders or tape |

| Metallic Screen | Copper Wires and/or Copper Tape (around individual cores) |

| Optional: Waterblocking - Longitudinal | Swellable Tape |

| Optional: Inner Sheath | Applied where Armour is also applied. PVC or LSZH compound |

| Optional: Armour | Single Core: Aluminium Wires / Tape Multi-Core: Galvanised Steel Wires / Tape (Wires can be circular or flat, tapes can be single or double layer flat or corrugated) |

| Optional: Waterblocking - Radial | Aluminium/PET Tape with the aluminium side tightly bonded to outer sheath |

| Outer Sheath | LDPE, MDPE (Low/Medium Density Polyethylene), PVC (Polyvinyl Chloride), LSZH (Low Smoke Zero Halogen). Additives to offer resistance to UV, oils & greases, water, flames, termites, and other environmental factors can be added as required. |

Regulatory Compliance - CPR for MV Cables:

It's important to identify early in the specification process whether regulatory requirements such as CPR compliance apply to the the cables you're selecting - it may impact the choice of construction and materials used. Is the cable being used in an internal installation or being terminated inside a building? Geographically where is the installation (is there a minimum CPR class to achieve in a cable)?

There are CPR compliant MV cables sheathed in PVC and LSZH materials, holding up to CPR Class Cca, and meeting relevant standards - including holding third-party approvals. It just speak to a member of the team and they can help guide you to a cable that meets your requirements.

MV Cable Sizes:

Our 10kV, 11kV, 20kV, 22kV, 30kV and 33kV cables are available in the following cross-sectional size ranges (depending on Copper/Aluminium conductors). Larger sizes are often available upon request.

| 10kV single core | 35mm2 to 500mm2 |

| 10kV 3-core | 35mm2 to 240mm2 |

| 11kV single core | 50mm2 to 1000mm2 |

| 11kV 3-core | 35mm2 to 400mm2 |

| 20kV single core | 50mm2 to 500mm2 |

| 20kV 3-core | 35mm2 to 630mm2 |

| 22kV single core | 50mm2 to 630mm2 |

| 22kV 3-core | 50mm2 to 500mm2 |

| 30kV single core | 50mm2 to 500mm2 |

| 33kV single core | 70mm2 to 1000mm2 |

| 33kV 3-core | 50mm2 to 400mm2 |

Support with MV Cable Specification

It's essential for the longevity and efficiency of your installation that the MV Cables you specify are closely optimised to match the requirements. For support with this, navigating the standards, construction and compliance requirements, you can contact our technical team by email on technical@elandcables.com or by telephone on +44 (0)20 7241 8500. We can discuss your specific project requirements and our international Medium Voltage cable and accessories solutions.

MV Cable Stockholding and Supply

Once you've identified the correct construction and standards, we can supply your MV cables against your project timelines - whether that's as an urgent requirement coming direct from stock, despatched same-day, or manufactured and delivered against your schedule, via our fleet - including using hiab self-offloading vehicles where needed.

Our MV cables are available in specific lengths as well as in extended long lengths to aid installation and to reduce the number of joints. Accompanying cable accessories, with the cable size calibrated to match seamlessly, can also be provided.

Testing Medium Voltage Cables

Given the critical nature of the infrastructure connection created with MV cables, reliability, quality and compliance are vital. To provide the necessary assurances of this to both electrical engineers and their end-user customers, we test our MV cables in our specialist testing facility.

Our MV facility is an extension of The Cable Lab where we undertake tests on cables of rated voltage 3.3/6.6kV and upwards. This includes key tests such as the cable integrity withstand test, also known as VLF testing to determine any failure in the sheathing material. It provides comprehensive quality assurance on British Standard and European/IEC standard MV cables, armoured or unarmoured, as well as industry-specific MV cables such as DNO 11kv and 33kv, and Network Rail trackside power 25/44kV.

Medium Voltage Cable

Your tailored quote direct to your inbox

Your basket is currently empty

Armoured Cable - SWA & AWA PVC Cable LSZH Cable Back to Overview

Project Services

Our extensive portfolio is backed by a wide range of services that help your project run smoothly, together providing a complete cable solution

Learn moreCable Testing

Learn more about our UKAS accredited ISO 17025 testing laboratory, our specialist MV test facility, and the tests that provide quality and compliance assurance

Read onCable calculator

Use our cable calculator to aid with cable sizing in accordance with British BS7671 and International IEC 60364-5-52 standards

Calculate cable size