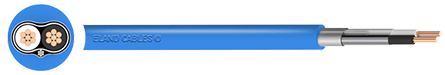

EN 50288-7 Cable

Project services

Our extensive portfolio is backed by a wide range of services that help your project run smoothly, together providing a complete cable solution

Learn moreCable Testing

Learn more about our UKAS accredited ISO 17025 testing laboratory, our specialist MV test facility, and the tests that provide quality and compliance assurance

Read onCable calculator

Use our cable calculator to aid with cable sizing in accordance with British BS7671 and International IEC 60364-5-52 standards

Calculate cable size