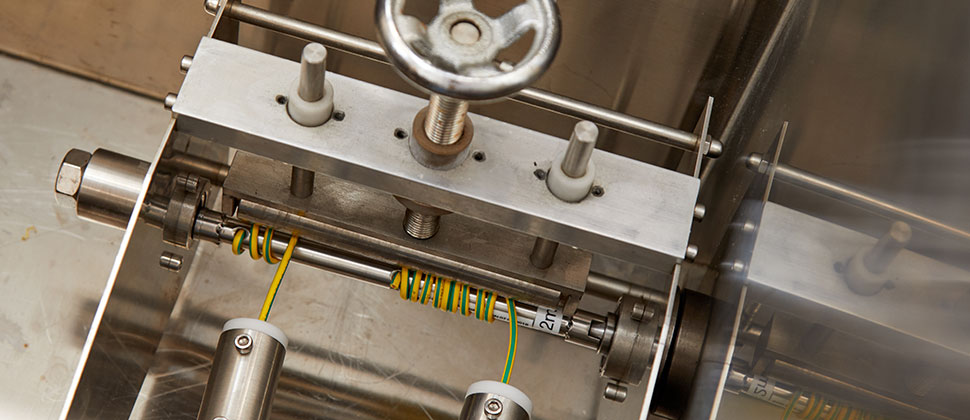

Cable Cold Bend Testing

The sample is clamped at the top to the mandrel before being wrapped once around it. The sample must then be conditioned inside the test chamber at the appropriate temperature for the particular polymer for a minimum of 16 hours. The conditioning duration can be reduced when specific pre-cooling criteria have been applied.

Once conditioning has been completed, the test sample is wound around the mandrel, following the number of turns as specified in Table 1 IEC 60811-504 (below) whilst the chamber maintains the same test temperature.

Table 1 IEC 60811-504 - Rotations of mandrel

| Overall Diameter of test piece (mm) | Number of Turns |

|---|---|

| < D ≤ 2.5 | 10 |

| 2.5 < D ≤ 4.5 | 6 |

| 4.5 < D ≤ 6.5 | 4 |

| 6.5 < D ≤ 8.5 | 3 |

| 8.5 < D | 2 |

Once wound, the chamber door can be opened and the sample removed without disturbance so that it can condition on the mandrel at room temperature for a further 60 minutes.

To be compliant with the Cold Bend Test the cable insulation or sheathing must not show any cracks, flaws or damage when visually inspected after unwinding.

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses