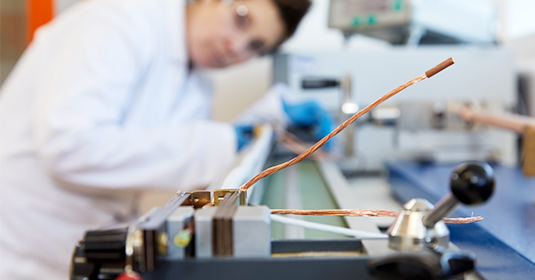

Conductor Resistance Testing

In order to record an accurate measurement for the test results of the conductor resistance, the sample must be kept in the test area for sufficient time to ensure that the conductor temperature has conditioned to a level which permits an accurate determination of resistance. Conductivity is directly related to temperature and the conductor resistance testing according to EN 60228 is based on a conductor temperature of 20°C.

Traditionally the conductor resistance test equipment is either a Kelvin Double Bridge or a Wheatstone Bridge, using the principle of balancing the voltage across known resistors to determine the unknown resistance. Modern equipment has been developed which determines the cable conductor resistance through the principle of Ohms law, calculating the current and voltage across the sample, and from this determining the resistance.

Accuracy for this cable test is typically in the region of 0.2 to 0.5%. A formula is used to correct these measurements to 20°C and the results are then compared to the standard for each conductor type and size.

Conductor resistance is a key cable test as conductors with too high a resistance pose a safety threat. When current passes through a conductor the inherent resistance causes a heating effect - if the resistance is too high the heat of the conductor may cause the premature failure of the insulation which may in turn result in a fire or short circuit.

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses