Cable Pressure Testing at High Temperatures

The Cable Lab conducts pressure testing for cables at high temperatures as part of our ongoing QA processes but this cable test is also available on third-party cables with independent report analysis.

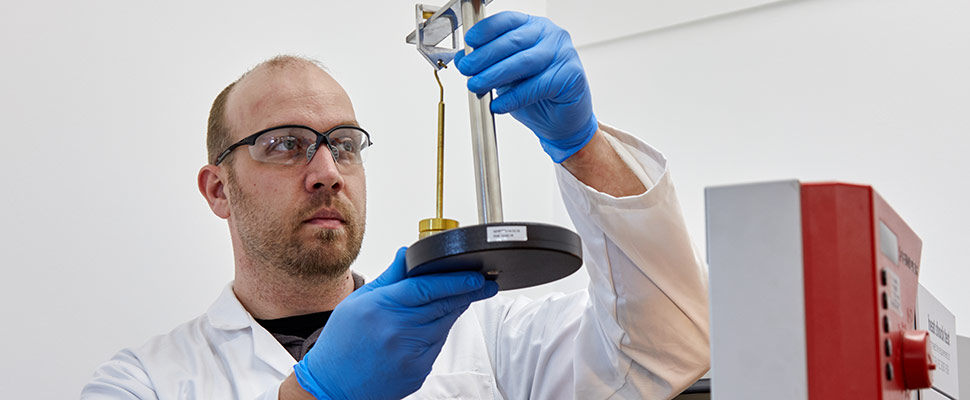

To accurately conduct pressure testing you need an air oven with natural circulation and an indenting device to apply pressure to the material surface. This indenting device is a rectangular blade with a thickness of 0.7mm which can be pressed perpendicularly against the test piece under the influence of an applied force.

The temperature of the oven and the force to be applied are determined by the standard for that material type. Similarly, the length of time the cable is left under pressure inside the oven is also determined this way. At the end of the specified duration the test piece is rapidly cooled under load by spraying the test piece with cold water on the spot where the blade is pressing. The test piece is then removed from the apparatus and cooled further by immersion in water.

Once the hot set pressure test has been conducted, a narrow strip is cut from the cable sample test piece and a measuring microscope is used to measure the indent left in the cable by the blade, to be expressed as a percentage of the sheath or insulation thickness. The result is recorded as a pass or fail based on the degree of permanent indentation allowed in the standard.

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses