Heat Shock Testing for Cables

The test method to determine the resistance of cable insulation and sheaths to cracking requires an air oven capable of maintaining the temperature within defined tolerances, and metal mandrels of sufficient length and diameter to wrap the cable samples around. These tests are performed under controlled conditions in the ISO 17025 laboratory.

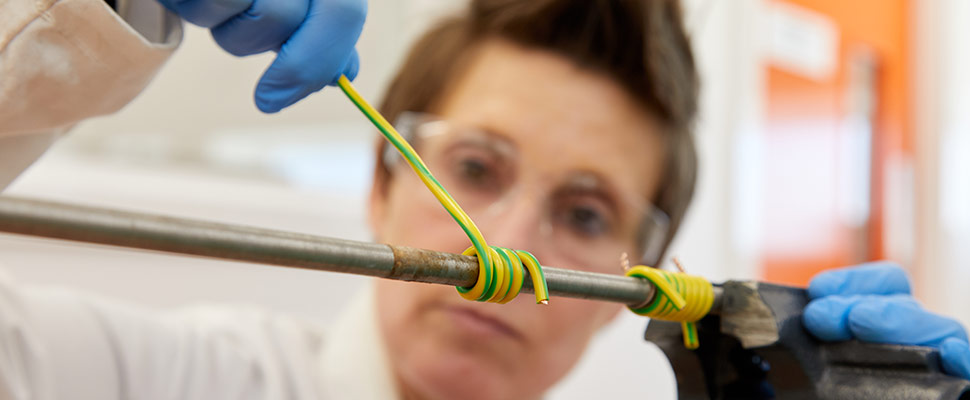

Prepared cable samples of sufficient lengths are tightly wound and fixed to form a helix around the mandrel. The diameter of the mandrel and the number of turns the sample must be wound is determined by the standard and based on the outer diameter of the cable under test. The samples are then placed in the oven which has been set at the temperature determined in the relevant standard (typically 150°C for 60 minutes).

After the specified time, the cable is removed and allowed to cool to ambient temperature before being examined for any cracks. The ambient temperature of our ISO 17025 cable testing facility is strictly controlled to ensure consistent test results unaffected by changes in room temperature. Pass or fail is based on any evidence of such cracks.

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses