Cable Sheath Resistance Testing

The voltage applied depends on the individual cable: for low voltage wires under 600V it is either 250Vdc, 500Vdc or 1000Vdc, whilst for medium voltage and high voltage cables the DC current upwards of 2500V (2.5kV) and 5000V (5kV). The current is applied for a period of 1 minute before being measured and recorded.

Sheath Resistance testing is often used by Network Rail to test the sheath integrity of their NR/PS/ELP/00008 graphite coated trackside power cables. The graphite coating provides a semi-conductive layer through which to pass the potential current across and in order to undertake the test this coating has to be rubbed off across a pre-determined length. The voltage applied is determined by the minimum average thickness of the sheathing material, equal to 8kV per millimetre of thickness, with a maximum of 25kV. This test is carried out whilst the cable is still on the cable drum to demonstrate no damage has been incurred during transit.

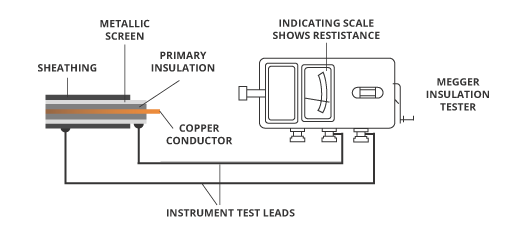

The cable is connected to a generator via connecting deflecting coils, joining the sheathing material and the metallic copper wire screen. This non-destructive test can identify any water penetration, moisture, current leakage, wiring short circuits, and deterioration in resistance, which in turn would indicate a fault in the sheath integrity.

Sheath resistance measurements to IEC 60364-6 should return as follows:

- Extra low voltage (test voltage 250Vdc) ≥ 0.5 MΩ

- Up to 500V (test voltage 500Vdc)≥ 1.0 MΩ

- Over 500V (test voltage 1000Vdc) ≥ 1.0 MΩ

It should be remembered that the minimum sheath resistance figure is determined against an ambient temperature of 20oC and any difference in this upon testing will require correction factors to be applied.

A similar test, with a 10kV potential is then conducted on the installed cable prior to jointing to ensure no further breakdown has affected the sheath integrity.

A cable sheath integrity test is also commonly used on DNO cable, albeit the distribution network operator cables do not have a graphite semi-conducting layer and so there is no need to remove it prior to testing.

The Cable Lab undertake Megger testing as part of their onsite assessment for fault diagnostics. Where applicable, a sample of affected cable would then be transferred to the laboratory for further testing including insulation resistance

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses