Static Flexibility Testing for Cables

Two clamps, A and B, are located at a height of at least 1.5 m above ground level. Clamp A is fixed, and clamp B can move horizontally at the level of clamp A. The ends of the sample are clamped vertically and remain vertical throughout the test.

With one end fixed and static in Clamp A and the other in the movable Clamp B, there is roughly a distance of 0.20 m between them. The cable takes roughly the shape indicated by the dotted lines.

Once the Static Flexibility test begins, the movable Clamp B is moved away from the fixed clamp A until the loop formed by the cable takes the shape, indicated by the heavy outline, of the U. It remains enclosed wholly between two plumb lines through the clamps and set up tangentially to the external generatrix of the cable. The test is conducted twice with the cable being turned through 180° in the clamp after the first test.

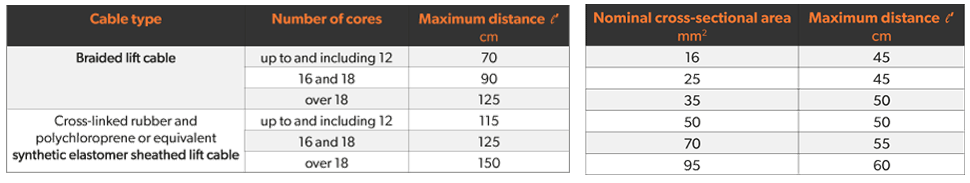

The mean of the two values is measured between the two plumb lines. For the cable to meet the requirements of the static flexibility test, thee mean of the two values shall not exceed the values specified in the below tables for arc-welding electrode cables and for lift cables.

Cable Sizing Calculator

Supporting Low Voltage cable sizing to BS and IEC standards with our easy-to-use calculator

Try it now

Custom Cable Design

Tailoring cables to meet bespoke requirements of performance or environmental challenges when off-the-shelf options are unavailable.

Read moreCPD Cable Training

Expert cable tuition from our experts with CPD-certified cable training and tailored cable learning programmes

Courses